Comprehensive Solutions for Precision Metal Laser Cutting

Table of Contents

Advanced Metal Laser Cutting Equipment for Modern Manufacturing #

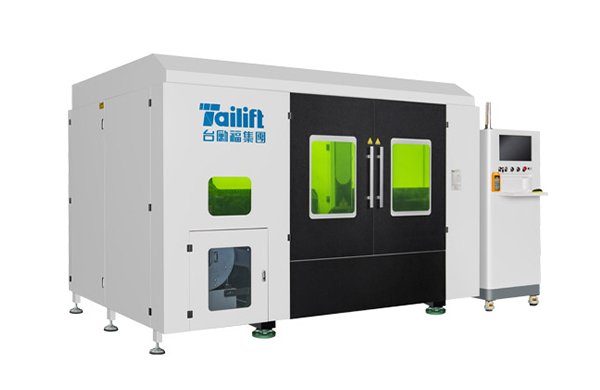

Tailift offers a robust selection of metal laser cutting equipment engineered to meet the evolving needs of precision metal fabrication. With over forty years of experience in industrial machinery, our solutions are tailored to deliver accuracy, efficiency, and long-term reliability for manufacturers worldwide.

Why Tailift Laser Cutting Machines Stand Out #

Our laser cutting machines are designed to handle a broad spectrum of metal materials, ensuring clean, rapid, and highly precise cuts. Whether your operations involve high-volume production or custom fabrication, Tailift systems are built for consistent performance and minimal downtime.

Key Features:

- Fiber laser sources from leading brands such as IPG, Raycus, and Max

- Automated sheet loading and unloading systems

- High-speed linear motor and gantry designs

- Intuitive user interface with real-time monitoring

Recommended Laser Cutting Models #

TE12025

TE12025

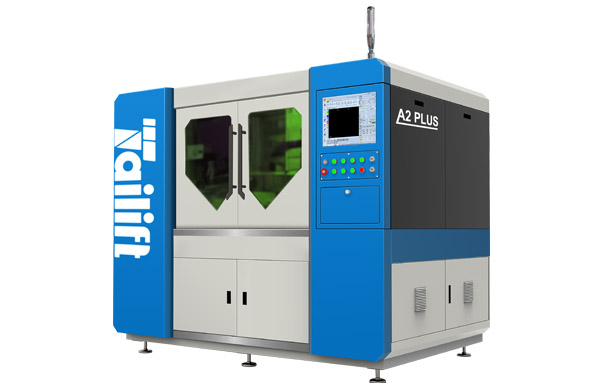

A2 PLUS

A2 PLUS

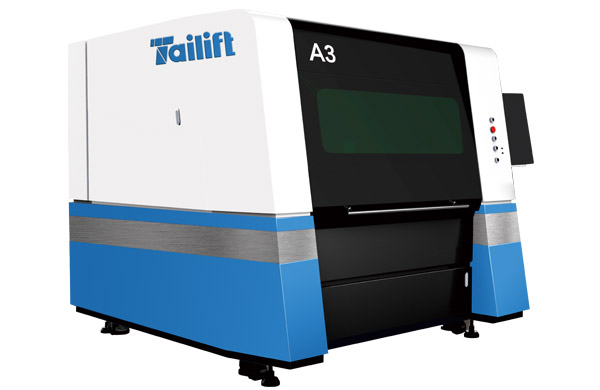

A3

A3

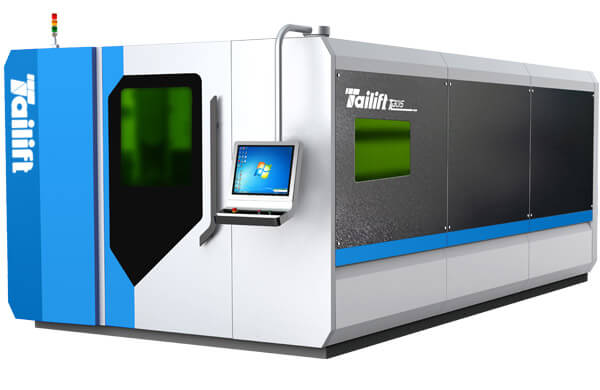

TL3015

TL3015

TL4020

TL4020

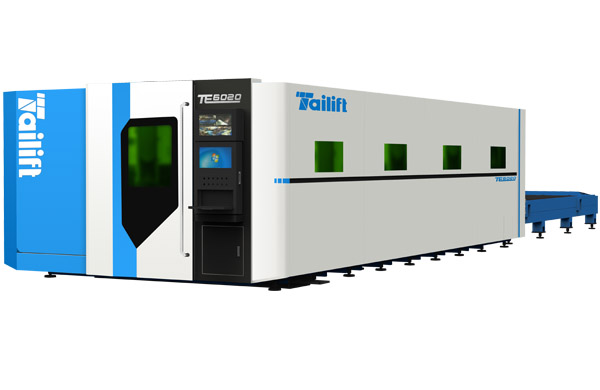

TL6020

TL6020

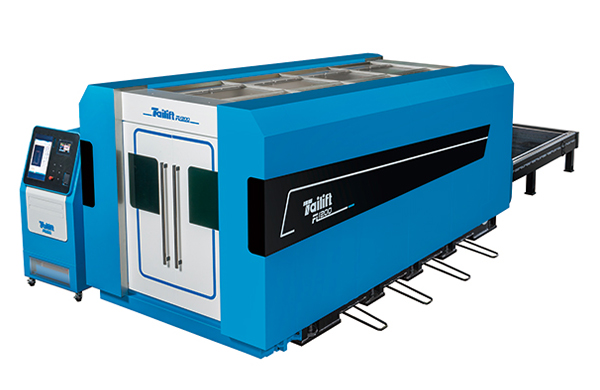

FL2000

FL2000

FL3015 / FL4020 / FL6020

FL3015 / FL4020 / FL6020

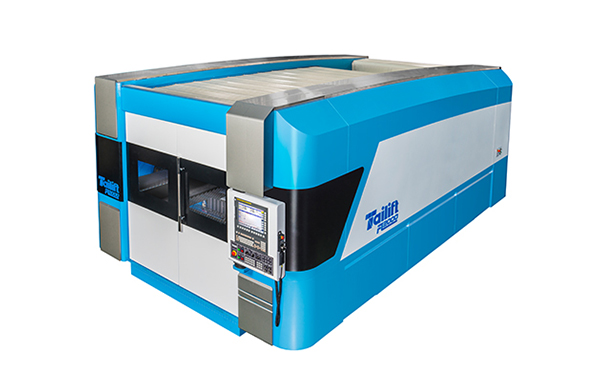

A3015

A3015

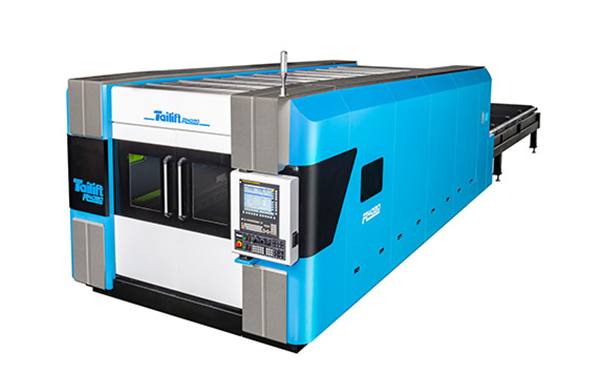

A3015-T6

A3015-T6

TL1515C

TL1515C

AT6012F

AT6012F

ATC6020L

ATC6020L

LW1500A/LW2000A

LW1500A/LW2000A

LW1000/LW1500/LW2000

LW1000/LW1500/LW2000

Model Highlights #

- TE12025: High-power laser system up to 40,000W, suitable for thick and heavy-duty metal cutting.

- TL1515C: Features full splash protection, OD6-grade fiber optic safety glasses, and emergency stop switches for enhanced safety.

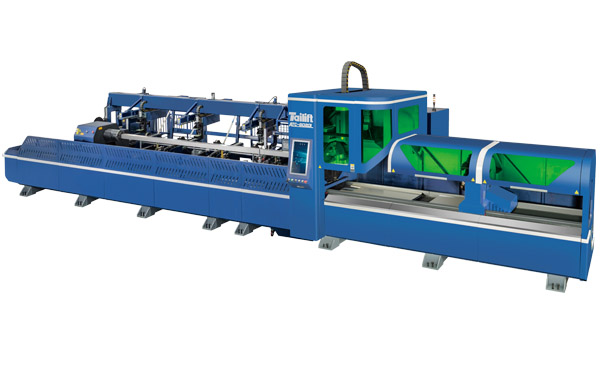

- A3015-T6: Combines sheet and pipe cutting capabilities in a single compact machine, ideal for limited space and budget.

Flexible Machine Selection #

Tailift provides a variety of machine types and configurations to suit different production requirements:

- Laser Sheet Metal Cutting Machines

- Sheet and Pipe Laser Cutting Machines

- Laser Pipe Cutting Machines

- Smart Laser Welding Equipment

- Handheld Laser Welding Machines

- Optical Fiber Laser Derusting Machines

Laser Power Options: 1000W, 1200W, 1500W, 2000W, 2500W, 3000W, 4000W, and up to 40,000W for select models.

Table Types: Single table, full splash cover with exchange table.

Available Work Area Sizes: 1300x900, 1500x1000, 1500x3000, 2000x4000, 2000x6000, 3000x1500, 4000x1500, 4000x2000, 6000x1500, 6000x2000, 1500x1500.

Applicable Industries: Transportation, technology, public facilities, advertising, vending machines, medical equipment, distribution boxes, and more.

Frequently Asked Questions #

What types of metal can Tailift laser cutting equipment handle?

Tailift machines are capable of cutting carbon steel, stainless steel, aluminum, brass, and copper. Cutting quality and speed depend on material thickness and selected laser power.

How does fiber laser compare with CO₂ laser?

Fiber lasers provide faster speeds, lower maintenance, and improved energy efficiency, especially for thin to medium-thick metals.

How do I choose the right laser power for my application?

Laser power selection depends on the type and thickness of metal. For example, 1kW–3kW is suitable for sheets up to 6mm, while 6kW–15kW is recommended for thicker or high-strength metals. Tailift’s technical team can provide personalized guidance.

What is the average lifespan of Tailift laser cutting machines?

With proper maintenance, Tailift systems can operate reliably for over 10 years.

Can Tailift machines be integrated into automated production lines?

Yes, automation options such as robotic arms, conveyors, and smart nesting software are available to streamline workflows.

What certifications do Tailift laser cutting machines have?

Tailift equipment is manufactured to meet CE, ISO, and other international standards for safety and quality.

Do you offer after-sales service and technical support?

Tailift provides global support, including installation, training, troubleshooting, and spare parts delivery to ensure optimal machine performance.

Explore More #

For further details or to discuss your specific requirements, contact Tailift and discover how our advanced metal laser cutting equipment can enhance your production capabilities.